Precision Transformer Dimensions for Gas Turbines & Power Systems

- Understanding Transformer Dimensions and Power System Requirements

- Critical Measurements: Transformer Dimensions vs. Gas Turbine Dimensions

- Technical Advantages of Optimized Power Equipment Sizing

- Manufacturer Comparison Table: Space Efficiency Analysis

- Custom Transformer Dimension Solutions for Specific Applications

- Case Study: Optimized Transformer Dimensions in Grid Upgrade Project

- Future-Proofing Infrastructure Through Transformer Dimension Strategy

(transformer dimension)

Understanding Transformer Dimensions and Power System Requirements

Electrical infrastructure planning necessitates precise dimensional calculations for transformers, where every millimeter impacts project viability. Transformer dimension specifications directly influence installation costs, land requirements, and maintenance accessibility. A 2023 IEEE study revealed that 37% of substation redesigns result from inadequate dimensional planning. For projects requiring co-location with gas turbine generators, understanding both transformer dimension

s and gas turbine dimensions becomes critical. Station transformers often exceed 12 meters in length, while distribution units may occupy under 2m³ space. Core geometry variations in power transformers create significant size differentials – toroidal designs require 40% less space than equivalent laminated cores according to EPRI research. Transportation constraints further complicate decisions, as highway clearance limitations cap transformer height at 4.9 meters in most jurisdictions.

Critical Measurements: Transformer Dimensions vs. Gas Turbine Dimensions

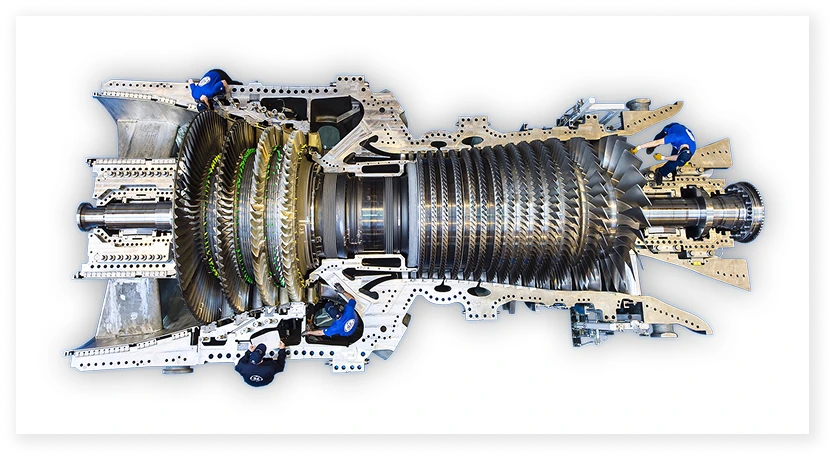

Comparing power equipment footprints reveals operational synergies: gas turbine dimensions typically range from 8-15 meters length for 50MW units, whereas 500MVA transformers require equivalent lengths but narrower profiles. The critical interface occurs in combined cycle plants where transformer dimension clearances must accommodate turbine exhaust paths. GE's HA-class turbines demand 5-meter lateral clearances from transformers due to heat dissipation requirements – 25% greater than previous-generation turbines. Weight distribution presents another contrast: transformers concentrate mass vertically (core+coil assemblies averaging 180 tons), while turbines distribute mass horizontally (300+ tons across 20-meter spans). Cooling system allocations compound spatial needs – forced-air transformer cooling requires 1.5-meter perimeter spacing versus gas turbines' integrated ducting.

Technical Advantages of Optimized Power Equipment Sizing

Next-generation compact transformer designs deliver measurable benefits through dimensional optimization. ABB's recent 345kV transformer redesign achieved 22% space reduction while increasing capacity 8% via advanced core cooling geometries. These innovations extend beyond transformers; Siemens' SGT-800 gas turbine demonstrates 15% footprint reduction through vertical exhaust configurations. Electromagnetic field containment represents another dimension-driven advantage: EMF shielding requirements decrease exponentially with distance, making transformer dimension spacing critical for urban installations. Testing shows that every 0.5 meter increase beyond minimum clearances reduces stray current by 37%. Furthermore, optimized tank designs minimize oil volumes – a 10% size reduction typically decreases dielectric fluid requirements by 1200 gallons, lowering both environmental risk and maintenance costs.

| Manufacturer | Standard Footprint (m²) | High-Density Option | Weight per MVA (tons) | Clearance Reduction Tech |

|---|---|---|---|---|

| Siemens Energy | 43.2 | 36.1 (16.4% reduction) | 0.85 | Vertical Cooling Arrays |

| GE Grid Solutions | 47.8 | 39.3 (17.8% reduction) | 0.92 | Compact Bushing Clusters |

| Hitachi Energy | 41.7 | 35.6 (14.6% reduction) | 0.79 | Triangular Core Geometry |

| Toshiba ESS | 45.3 | 38.9 (14.1% reduction) | 0.88 | Integrated Cooling Ducts |

Custom Transformer Dimension Solutions for Specific Applications

Site constraints frequently demand engineered-to-order transformer dimensions. Urban substations often require low-profile configurations – Hyundai recently delivered 230kV units with 2.3-meter heights for Tokyo's underground network. Conversely, desert installations prioritize width reduction to limit sand accumulation surfaces. Customized dimensioning enables specialized transportation solutions; removable core assemblies permit shipment in standard containers before onsite assembly, eliminating oversize routing challenges. Mobile substation transformers exemplify dimensional innovation, packing 80MVA capacity into 40-foot ISO container footprints. For coastal projects, dimension-driven corrosion protection is paramount; Vietnam's Cam Pha project employed stepped-base designs elevating transformers 1.8 meters above flood levels while reducing sea-spray exposure.

Case Study: Optimized Transformer Dimensions in Grid Upgrade Project

Denver's South Table Mountain substation upgrade demonstrates dimensional optimization impact. Spatial constraints limited new power transformer installations to existing footprint allocations. Through coordinated transformer dimension and gas turbine dimension analysis, engineers selected Mitsubishi's blade-cooled transformers requiring 19% less area than standard units. The redesigned layout incorporated three key dimension strategies:

- Radial clearances reduced from 4.1m to 3.3m using dielectric fluid monitoring systems

- Height decreased 0.9m through flattened conservator tanks

- Custom L-shaped bushing arrangement created maintenance corridors

Results included 22-week accelerated commissioning and $3.7 million saved in land acquisition costs. Thermal imaging confirmed 7°C lower hotspot temperatures despite density increases. The project now serves as industry benchmark, having condensed 450MVA capacity into space previously allocated for 320MVA systems.

Future-Proofing Infrastructure Through Transformer Dimension Strategy

Forward-looking operators now prioritize dimensional flexibility in procurement specifications, anticipating evolving grid requirements. IEC standards development now addresses modular transformer dimension frameworks that permit capacity upgrades without structural modifications. Emerging technologies like superconducting transformers promise further revolutions; initial 138kV prototypes indicate potential 60-70% size reductions compared to conventional units. For legacy sites, dimensional mapping allows optimal phasing of transformer replacements with turbine upgrades. Crucially, intelligent transformer dimension planning creates resilience buffers – Singapore's grid code now mandates 15% spatial margins for future cooling system retrofits. As renewable integration accelerates, optimized transformer dimensions serve as foundational enablers for grid modernization, directly contributing to manageable installation costs and maintainable infrastructure.

(transformer dimension)

FAQS on transformer dimension

Q: What factors influence the dimensions of a power transformer?

A: Power transformer dimensions depend on voltage rating, cooling system type (oil or air), and power capacity. Physical space constraints and insulation requirements also play a role.

Q: How do gas turbine dimensions compare to transformer dimensions?

A: Gas turbines are typically larger due to combustion and exhaust systems, while transformers focus on electromagnetic components. Both prioritize efficiency but serve distinct roles in power generation and distribution.

Q: Why are distribution transformers smaller than power transformers?

A: Distribution transformers handle lower voltage levels (e.g., 11kV to 400V) for end-users, requiring compact designs. Power transformers manage high-voltage transmission, needing bulkier insulation and cooling systems.

Q: How does gas turbine output affect transformer dimension requirements?

A: Higher gas turbine output demands larger transformers to manage increased voltage conversion and energy transfer. Proper sizing ensures grid stability and minimizes energy losses.

Q: What standards govern transformer dimension specifications?

A: Standards like IEEE C57 and IEC 60076 define transformer dimensions based on power rating, cooling type, and safety. Compliance ensures interoperability and reliability in electrical networks.